The Tanning Process

The majority of riding equipment is made of leather due to its unique and durable properties.

Leather is a material derived from hide or skin that has undergone a tanning process to enhance its durability. This process is highly skilled and time-consuming, often taking up to two weeks to complete.

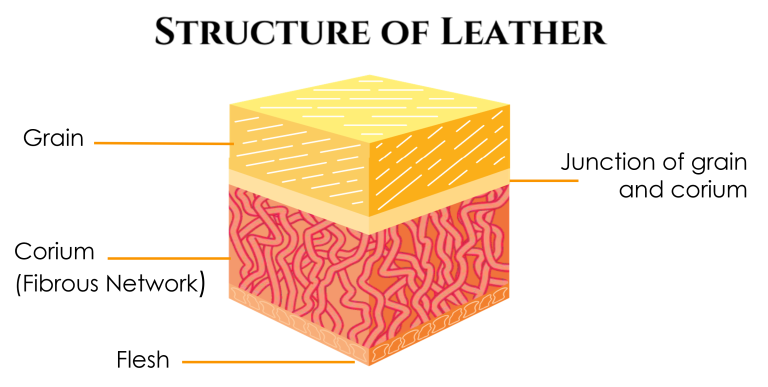

The finished side of the leather is called the GRAIN, which is typically dyed and embossed to provide a uniform texture and conceal any imperfections.

Beneath the grain is the CORIUM, which consists of protein and collagen fibers arranged in a spaghetti-like structure. These fibers give leather its strength, durability, and flexibility.

On the underside is the FLESH side, which comes into contact with the horse. This side is rougher and more absorbent, making it prone to losing moisture. However, it is also more porous and can readily absorb conditioners and oils.

Finished leather typically contains approximately 10% fats and oils, along with around 14% water. These components play a crucial role in providing lubrication for the collagen fibers within the leather. The remaining balance consists of protein. It is important to regularly care for and clean leather to maintain this balance and preserve its resilient properties. Proper care helps ensure that the fats, oils, and moisture within the leather are maintained, contributing to the overall durability and flexibility of the material.

Grades of Leather

Leather hides can differ in thickness depending on factors such as the type of animal, its age, and its sex. To achieve the desired thickness for a specific application, the hide is typically divided into two sections or layers and then processed accordingly. In the context of saddle-making, the highest quality saddles often use only the top grain leather, which refers to the outermost layer of the hide. This top grain leather is valued for its superior quality and durability, making it an ideal choice for crafting high-quality saddles.

Sources of Leather

Cow hide : Is a bi-product of the cattle industry. It is readily available, cost effective and renowned for its durability.

Calfskin : Produces soft and supple leather with few imperfections. Most commonly used in Europe.

Buffalo hide : Another durable type of leather. Most commonly sourced in the USA and Asia.

Pig skin: Soft & Fine

Leather Finishes

Full Grain Leather

The grain surface of the leather used for saddlery is typically left uncorrected, meaning it has not been buffed or altered. However, to enhance the appearance and durability of the leather, multiple coats of pigment may be added, and in some cases, a deeper grain pattern may be embossed. This process helps create a resilient and long-lasting leather that is commonly utilized in saddlery.

Corrected Grain Pigmented

Leather: The grain has been buffed and sanded to minimise imperfections and to prepare the surface for pigment coating. An artificial grain may be applied creating a uniform surface. Due to these many layers of pigment coating, the breathability of this leather is reduced and it may have a stiffer feel.

Aniline: A form of finishing that does not use pigments and so produces a very natural looking leather. As grain imperfections cannot be hidden, only the very best quality hides can be used, making such leather more expensive. Due to a minimal protective finish, aniline leather can have less resistance to staining and discolouration, so care should be taken to protect it.

Nubuck/Suede: Nubuck is very fine due to the tight fibre structure in the grain layer, whereas suede has a looser fibre structure with a distinctive rougher nap. Nubuck and suede require specialist cleaning to prevent damage and staining of the nap.

Vegetable Tanned: Uses vegetable extracts in the tanning process to give a natural looking, brown coloured leather. The colour of this leather improves and darkens naturally with age.

Finished Leather Specifically For Saddles & Bridles

Cowhide is the most commonly employed leather for tack due to its remarkable durability and strength. In more expensive saddles, other types of leather such as calfskin, pigskin, or suede may be used, particularly for areas like the knee pads and skirt. The preferred choice is typically the top grain cut of the leather, which is further enhanced with a pigmented finish to augment durability and resistance against staining.

English and European leather are highly regarded for their superior quality. This distinction arises from both the excellence of the original hides and the meticulous adherence to traditional manufacturing processes.

Cheaper alternatives often employ dyes that are not colorfast, making them susceptible to discoloration and exhibiting poor resistance to wear and tear. Consequently, such items may develop cracks and splits with minimal use.

Learn more about the significance of caring for your tack and safeguarding your investment.